The Automatic Cutting Machine is an industrial automation project developed using the Controllino Mega PLC, designed to feed and cut materials automatically with high precision and repeatability.

This system allows both manual control for testing and setup and fully automatic operation for continuous cutting cycles.

It’s ideal for applications such as wire cutting, tubing, plastic extrusion, packaging strips, or sheet material processing, where accurate feeding and cutting sequences are essential.

Objective of Automatic Cutting Machine using Controllino Mega PLC

The purpose of this project is to automate the feeding and cutting process of a material — for example, wire, pipe, or sheet — by using two stepper motors and AC motors controlled through relays.

The system eliminates manual handling, ensuring consistent cutting lengths and synchronized operation of the feeding and cutting units. It provides easy operation through push buttons and offers adjustable parameters such as speed, number of steps, and loop count, which can be configured directly in the Arduino IDE.

What is Controllino Mega PLC?

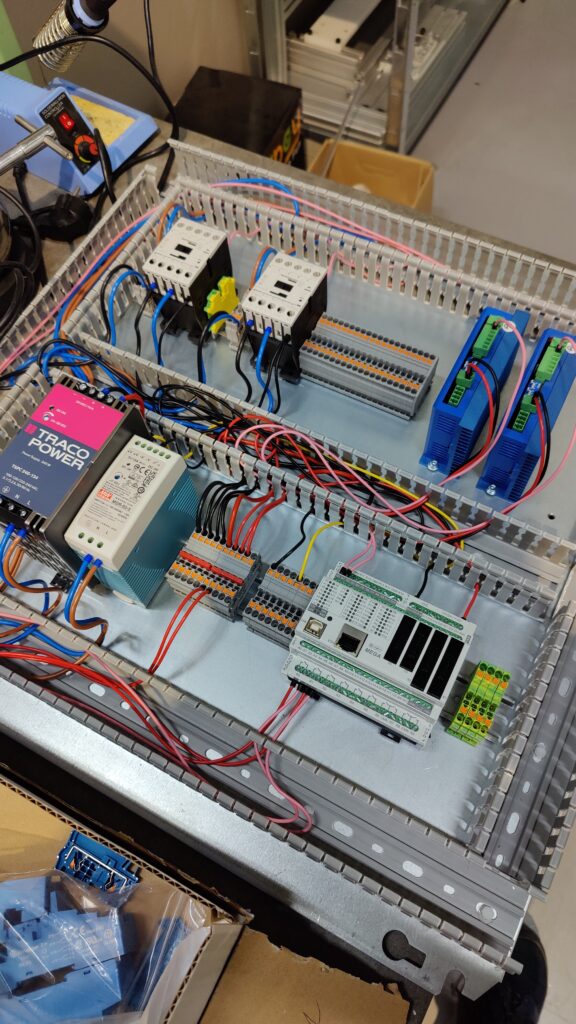

At the heart of this automation system is the Controllino Mega PLC, a professional-grade Arduino-based controller designed for industrial use.

It combines Arduino flexibility with PLC reliability, featuring:

- 24 V DC compatible digital I/Os

- Integrated relays for controlling AC motors

- Opto-isolated inputs for industrial sensors and buttons

- Compatibility with stepper motor drivers

- DIN-rail mountable housing for control panels

By using Controllino, the system achieves industrial durability, organized wiring, and safe power handling while remaining easily programmable in the Arduino IDE.

Why we Used Controllino Mega PLC Instead of a Regular Arduino Board?

While a normal Arduino board could theoretically perform similar logic, the Controllino PLC offers several major advantages:

Advantages Controllino Mega PLC:

- Industrial-grade reliability with optically isolated I/Os

- Built-in 24V digital inputs and relay outputs

- Ready for 230V motor control without extra modules

- DIN-rail mountable for control cabinets

- CE and UL certified for industrial environments

- Easier to integrate into factory automation setups

Limitations of Basic Arduino Boards:

- No built-in electrical isolation (risk of damage from relays/motors)

- Limited current handling

- Requires external relay boards and wiring

- Not compliant for industrial certification

Using the Controllino Mega ensures a safe, clean, and professional-grade automation solution.

Components used in Automatic Cutting Machine Project

| Component | Description | Function |

|---|---|---|

| Controllino Mega PLC | Arduino-based industrial controller | Central control unit |

| Stepper Motor (Feeder) | Driven via stepper driver | Feeds material forward by programmed length |

| Stepper Motor (Cutter) | Driven via stepper driver | Controls cutting blade movement (forward & backward) |

| Motor Relays (K1, K2) | 230V AC control via PLC | Operates auxiliary motors or actuators |

| Push Buttons (Start, Stop, Feed, Cut, Auto) | Manual input controls | Allows both manual and auto operation modes |

| Stepper Drivers | Interface between PLC and motors | Controls step/direction/enable signals |

| Power Supply (24V/230V) | Industrial power source | Powers PLC, relays, and motors |

Working Process Automatic Cutting Machine:

Manual Mode (Individual Control)

Each function of the machine can be operated manually for testing and calibration:

- Start Button: Turns on Motor Relay K1.

- Stop Button: Turns off Motor Relay K1.

- Feed Button: Rotates the feeder stepper motor clockwise for a configurable number of steps (length of feed).

- Cut Button: Activates Motor Relay K2 and rotates the cutting stepper motor forward, then backward, with a 500 ms delay between directions.

This mode helps operators fine-tune the feeding length and cutting stroke before switching to full automation.

Automatic Mode

When the Auto Button is pressed, the machine runs through a complete automated cutting cycle in a defined sequence:

- Activate Motor Relay K1 → Starts feeding motor or main drive.

- Delay 1 second

- Feeder Stepper Motor → Moves material forward by a defined number of steps (feed length).

- Delay 1 second

- Activate Motor Relay K2 → Turns on the cutting mechanism.

- Delay 1 second

- Cutting Stepper Motor (Forward) → Moves cutting blade forward by a programmable number of steps.

- Delay 500 ms

- Cutting Stepper Motor (Reverse) → Moves blade back to home position.

- Turn off Relays K1 & K2 → Ends one cutting cycle.

This sequence can repeat automatically for a predefined number of loops, which can be adjusted via the Arduino IDE.

Adjustable Parameters of Automatic Cutting Machine

All key parameters such as:

- Stepper speed,

- Number of steps for feed and cut,

- Loop count, and

- Delay durations

can be modified directly in the Arduino code.

This flexibility allows the system to adapt to different materials, cutting lengths, and operational requirements.

Code for Automatic Cutting Machine using Controllino Mega PLC

#include <Controllino.h> /* Usage of CONTROLLINO library allows you to use CONTROLLINO_xx aliases in your sketch. */

bool flag_1=true ,flag_2=true ,flag_3=true ,flag_4=true ,flag_5=true ;

bool Auto_Start= false;

int AUTO_LOOP = 3;

int AUTO_FEEDER_Steps = 800;

int AUTO_CUTTER_Steps = 500;

int SPEED = 2000;

// The setup function runs once when you press reset (CONTROLLINO RST button) or connect power supply (USB or external 12V/24V) to the CONTROLLINO.

void setup() {

// initialize necessary pin as input pin

pinMode(CONTROLLINO_D0, OUTPUT);

pinMode(CONTROLLINO_D1, OUTPUT);

pinMode(CONTROLLINO_D2, OUTPUT);

pinMode(CONTROLLINO_D3, OUTPUT);

pinMode(CONTROLLINO_D4, OUTPUT);

pinMode(CONTROLLINO_D5, OUTPUT);

pinMode(CONTROLLINO_A0, INPUT);

pinMode(CONTROLLINO_A1, INPUT);

pinMode(CONTROLLINO_A2, INPUT);

pinMode(CONTROLLINO_A3, INPUT);

pinMode(CONTROLLINO_A4, INPUT);

pinMode(CONTROLLINO_R0, OUTPUT);

pinMode(CONTROLLINO_R1, OUTPUT);

digitalWrite(CONTROLLINO_R0,HIGH);

digitalWrite(CONTROLLINO_R1,HIGH);

// please note that CONTROLLINO MINI has 5 more analog inputs A1 - A5

// please note that CONTROLLINO MAXI has 9 more analog inputs A1 - A9

// please note that CONTROLLINO MEGA has 15 more analog inputs A1 - A15

// All of them work in the same way like A0.

// Initialize serial communication at 9600 bits per second.

// Use Tools->SerialMonitor to see the messages.

Serial.begin(9600);

}Applications of Automatic Cutting Machine

This PLC-based cutting system can be adapted for a variety of industries:

- Textile / Rope Cutting Machines

- Plastic Tube or Pipe Cutting Systems

- Wire & Cable Cutting Equipment

- Packaging & Label Feeders

- Chemical or Dosing Process Feed Systems

It provides excellent control accuracy, flexibility, and reliability for repetitive cutting operations.

Key Features & Benefits of our Solution

- Dual-stepper motor control (Feed & Cut)

- Manual and automatic operating modes

- Adjustable feed and cutting parameters

- Controllino PLC for safe industrial operation

- Clean wiring and easy maintenance

- Scalable and reprogrammable logic

Conclusion

The Automatic Cutting Machine using Controllino Mega PLC is a compact yet powerful automation project showcasing how Arduino-based PLCs can deliver industrial-grade performance in real applications.

With configurable control logic, robust hardware, and precision motor control, this project stands as a perfect example of product design and development merging with industrial automation.

At Arduino Expert, we design and build such custom PLC-based systems to automate real-world processes — offering cost-effective, reliable, and IoT-ready solutions for industries worldwide.

Need This Project?

If you need this Automatic Cutting Machine System with or without Modifications or Customization then you can contact us through WhatsApp. We can deliver you the Fully Functional Project with Hardware/Components Shipment:

if you can not make this project yourself then you can use this option. We will assemble the Project and will ship it to your Doorstep with Safe Packaging.

Learn More about the services we offer.