In today’s rapidly evolving manufacturing landscape, industrial automation is no longer optional — it is essential. Modern production lines demand precision, reliability, quality assurance, and safety integration at every stage of operation. To meet these growing industry requirements, Arduino Expert successfully designed and developed a fully customized Automated Conveyor Control and Inspection System for one of our industrial clients.

This project demonstrates our expertise in Product Design and Development, Industrial Project Development, Custom Electronics Project Development, and Embedded Systems Development for real-world manufacturing applications.

The system is built around an Arduino-based embedded control architecture and simulates a multi-stage industrial production line where materials are:

- Transported

- Mechanically processed

- Heated

- Cooled

- Inspected

- Classified as Pass or Fail

All operations are fully automated using sensor-driven logic and actuator control, ensuring high efficiency and consistent performance.

Purpose of the Project

The primary objective of this project was to develop a scalable, modular conveyor automation solution that can:

- Improve production efficiency

- Minimize human intervention

- Automate quality inspection

- Implement process-based heating and cooling cycles

- Ensure operational safety through emergency controls

- Provide a customizable embedded firmware platform for future upgrades

As part of our Industrial Automation services, the solution was engineered to simulate real industrial workflows while maintaining flexibility for future expansion.

Project Overview Automated Conveyor Control

This project was developed as part of our Industrial Project Development Services for a manufacturing client looking to automate and optimize their material handling process.

The system includes:

- Dual conveyor motor control

- Multi-stage process automation

- Sensor-based object detection (S1, S2, S3, S4, S5)

- Heating and cooling control

- Automated inspection logic

- Pass/Fail indication system

- Emergency stop safety mechanism

- Embedded logic-based process sequencing

This solution demonstrates our expertise in Embedded Systems Development and Custom Electronics Product Design for industrial automation.

Working Principle of Automated Conveyor Control and Inspection System

T he Automated Conveyor System follows a structured industrial workflow:

Stage 1 – Material Transportation (Conveyor 1)

- The system starts when the operator presses the Start button.

- Conveyor 1 transports the material forward.

- Sensor S1 detects object arrival at the actuator station.

- Conveyor 1 automatically stops.

This ensures precise positioning using sensor feedback.

Stage 2 – Actuator Processing

- Once S1 detects the object, an Actuator mechanism activates.

- After processing, Sensor S2 confirms completion.

- Conveyor 2 starts moving forward.

This stage demonstrates intelligent coordination between mechanical and electronic subsystems,

Stage 3 – Heating Process

- Sensor S3 detects arrival at heating station.

- Conveyor stops automatically.

- Heater activates for controlled duration.

- Conveyor resumes movement.

This simulates industrial thermal processing.

Stage 4 – Cooling Process

- Sensor S4 detects object at cooling zone.

- Conveyor stops.

- Cooling fan activates.

- Conveyor resumes.

The heating and cooling cycle is repeated multiple times for process simulation.

Stage 5 – Automated Inspection System

- Sensor S5 detects object at inspection point.

- Conveyor stops.

- Buzzer alerts operator.

- System waits for inspection confirmation.

Inspection Logic:

- If operator confirms within 5 seconds → PASS

- If no confirmation → FAIL

LED indicators display result:

- Green LED → PASS

- Red LED → FAIL

This demonstrates real-world Quality Control Automation.

Safety & Emergency Control

Industrial systems require safety-first architecture.

This system includes:

- Dedicated Emergency Stop Button

- Continuous stop monitoring during all loops

- Immediate motor shutdown on stop trigger

Safety design is a key part of our Industrial Embedded Systems Development approach.

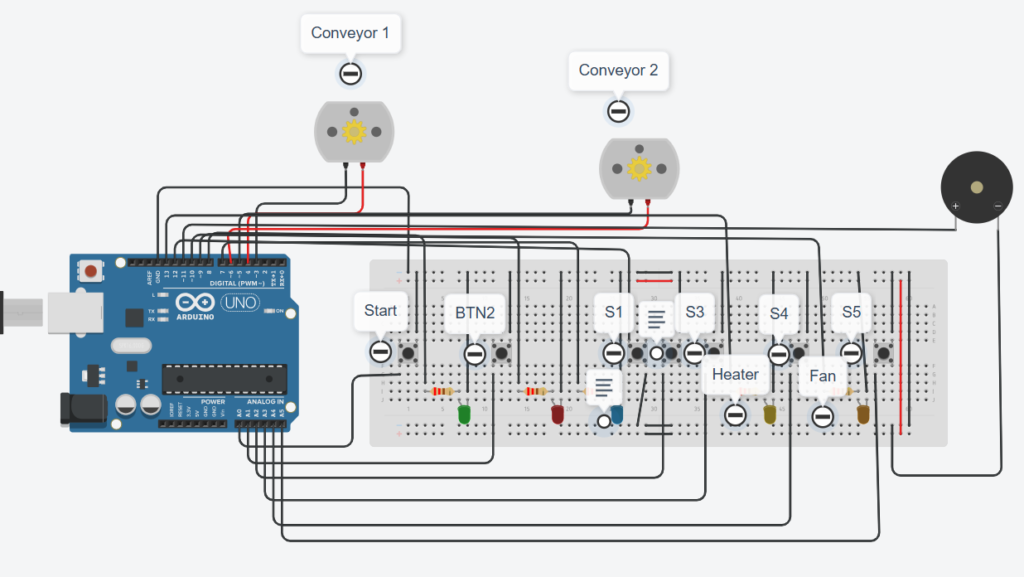

Circuit Diagram of Arduino-Based Smart Conveyor Automation System

Arduino Code for Custom Industrial Conveyor and Inspection System

int motorPin1 = 3;

int motorPin2 = 4;

int motorPin3 = 5;

int motorPin4 = 6;

int Actuator = 7;

int Green = 8;

int Red = 9;

int Fan = 10;

int Buzzer = 11;

int Heater = 13;

int S1 = 12;

int StartButton = A0;

int StopButton = A1;

int S2 = A2;

int S3 = A3;

int S4 = A4;

int S5 = A5;

int val;

void setup() {

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(motorPin3, OUTPUT);

pinMode(motorPin4, OUTPUT);

pinMode(Actuator, OUTPUT);

pinMode(Green, OUTPUT);

pinMode(Red, OUTPUT);

pinMode(Fan, OUTPUT);

pinMode(Buzzer, OUTPUT);

pinMode(Heater, OUTPUT);

pinMode(S1, INPUT_PULLUP);

pinMode(StartButton, INPUT_PULLUP);

pinMode(StopButton, INPUT_PULLUP);

pinMode(S2, INPUT_PULLUP);

pinMode(S3, INPUT_PULLUP);

pinMode(S4, INPUT_PULLUP);

pinMode(S5, INPUT_PULLUP);

// Initialize all outputs to LOW

digitalWrite(Red, HIGH);

digitalWrite(Green, LOW);

digitalWrite(Buzzer, LOW);

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

digitalWrite(motorPin3, LOW);

digitalWrite(motorPin4, LOW);

digitalWrite(Actuator, LOW);

digitalWrite(Heater, LOW);

digitalWrite(Fan, LOW);

}

Key Technical Features

- Arduino-based Embedded Control

- Multi-sensor industrial logic

- Dual motor H-Bridge control

- Bidirectional conveyor movement

- Timer-based process control

- Inspection decision window

- Industrial workflow simulation

- Modular and scalable architecture

Applications of Smart Manufacturing Conveyor Control System

This Automated Conveyor System can be used in:

- Manufacturing Production Lines

- Packaging Industries

- Assembly Units

- Food Processing Plants

- Quality Inspection Systems

- Industrial Training Institutes

- Automation Demonstration Labs

Our Related Services

Conclusion

The Automated Conveyor Control and Inspection System demonstrates our capability in delivering reliable, scalable, and intelligent industrial automation solutions.

From Product Design and Development to Industrial Embedded Systems Implementation, ArduinoExpert provides end-to-end engineering solutions for manufacturing and automation industries.

Need Help/Assistance in Custom Industrial Automation Project Development?

If you need this Arduino-Based Smart Conveyor Automation System Project with or without Modifications or Customization then you can contact us through WhatsApp. We can also provide you Zoom Assistant.

If you are Interested in a similar custom solution? Explore our Embedded Systems Development and Arduino Project Development services.