This Arduino-based Measurement Wheel device is designed to measure the exact linear distance in millimeters traveled by a rotating wheel. It’s especially useful for woodworking, CNC setups, and any scenario where precise on-the-fly distance tracking is essential. The device system also incorporates adjustments for blade thickness and tilt angle, making it a smart tool for machine operators and makers who demand precision in movement-based processes.

Features of Measurement Wheel Device for Wood Cutting Saw with Arduino:

As you push a piece of wood through a table saw or cutting guide, this Device tracks the actual length the blade has cut using a high-resolution rotary encoder attached to a tracking wheel. It also accounts for:

- Blade thickness (kerf)

- Tilt angle of the blade (for diagonal cuts)

- Real-time distance monitoring on an LCD

- Visual alignment via RGB LEDs

- Settings adjustments with rotary encoders and a push button

Everything is processed and displayed live using an Arduino Nano, giving you an accurate and user-friendly experience.

Working of Measurement Wheel Device for Wood Cutting Saw:

Length Calculation:

A 600 PPR rotary encoder tracks the wheel as it moves along the wood. The encoder’s pulse count is converted to millimeters based on the diameter of the tracking wheel. The formula is:

Cut Length (mm)=(600Pulse Count)×π×Wheel Diameter (mm)

Smart Compensation Logic:

- Blade Thickness Adjustment:

Users can configure the blade’s kerf width. This value is factored into the measurement to reflect net material removed. - Tilt Angle Compensation:

When cutting at an angle, the effective cutting length differs from the wheel’s travel. The tilt angle encoder allows the Device to apply trigonometric corrections to reflect the true cut length.

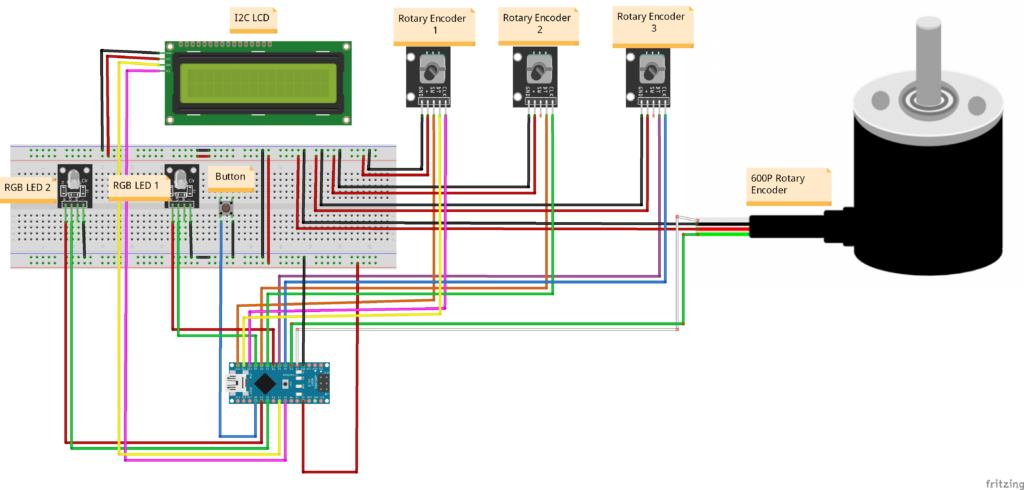

Components used in Measurement Wheel Device Project:

| Component | Description |

|---|---|

| Arduino Nano | Core controller |

| 600 PPR Rotary Encoder | Measures wheel rotation for precise tracking |

| Rotary Encoder (Blade Thickness) | Adjusts kerf width compensation |

| Rotary Encoder (Tilt Angle) | Configures blade tilt for accurate length correction |

| RGB LEDs | Visual feedback: alignment, error, or Device state |

| LCD Display (I2C 16×2 or 20×4) | Shows live cutting length and configuration values |

| Push Button | Used to reset length counter or enter settings mode |

| Power Source (5V DC or USB) | Powers the Device |

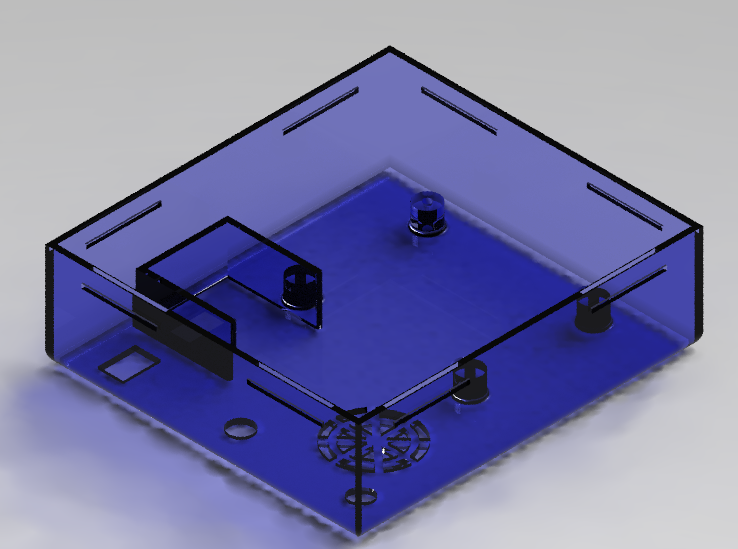

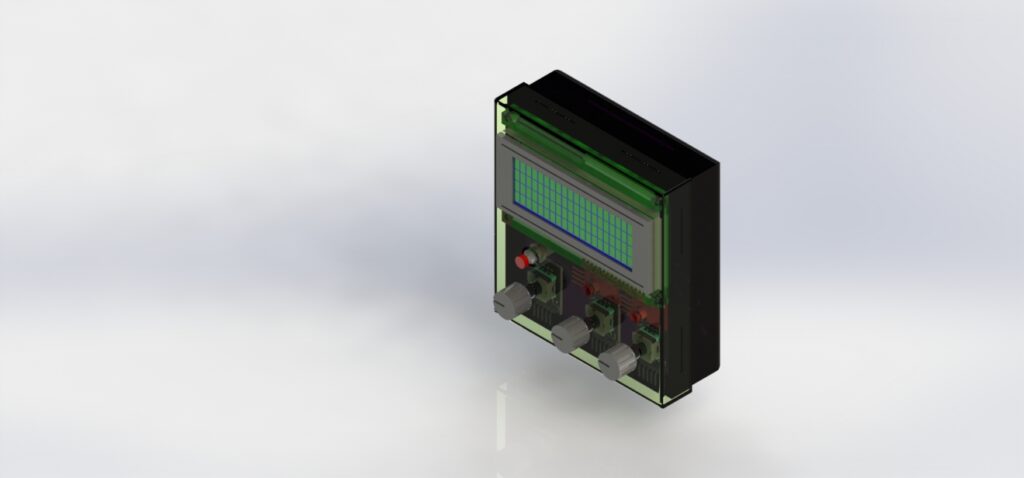

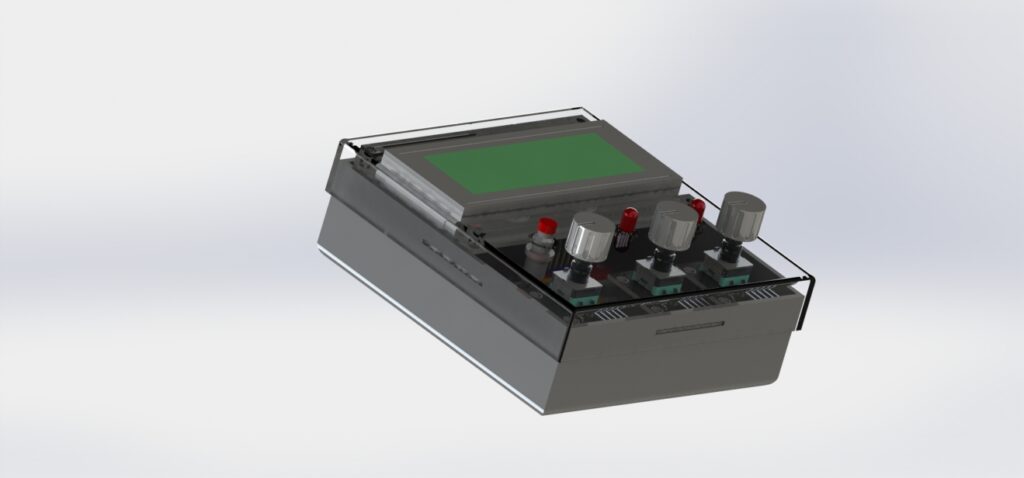

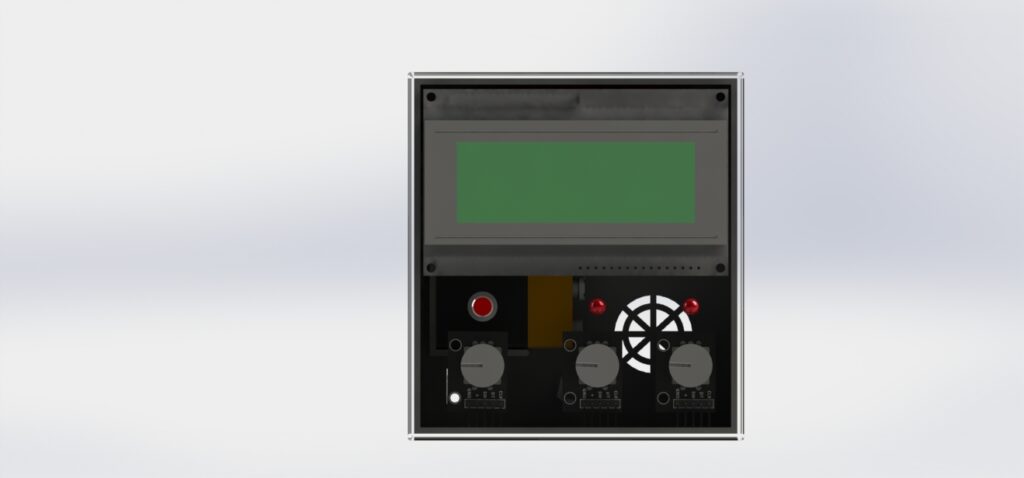

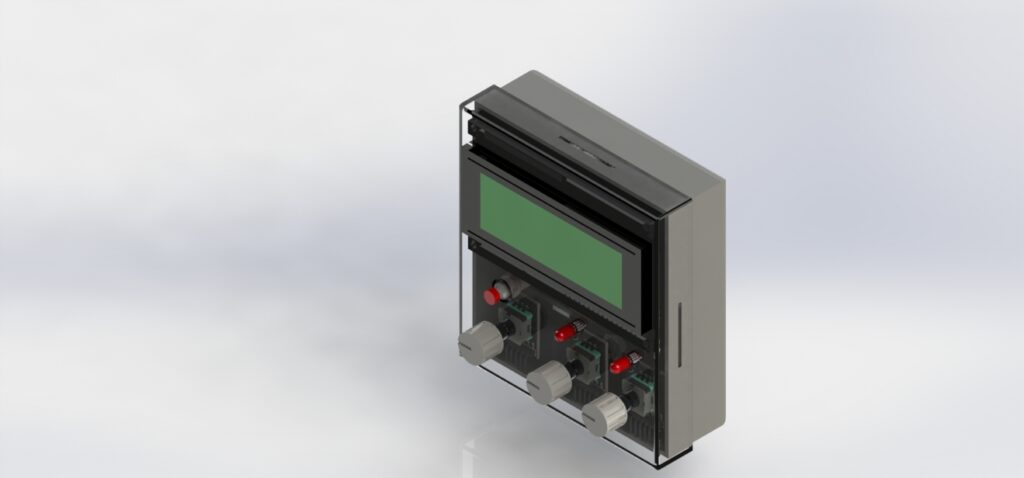

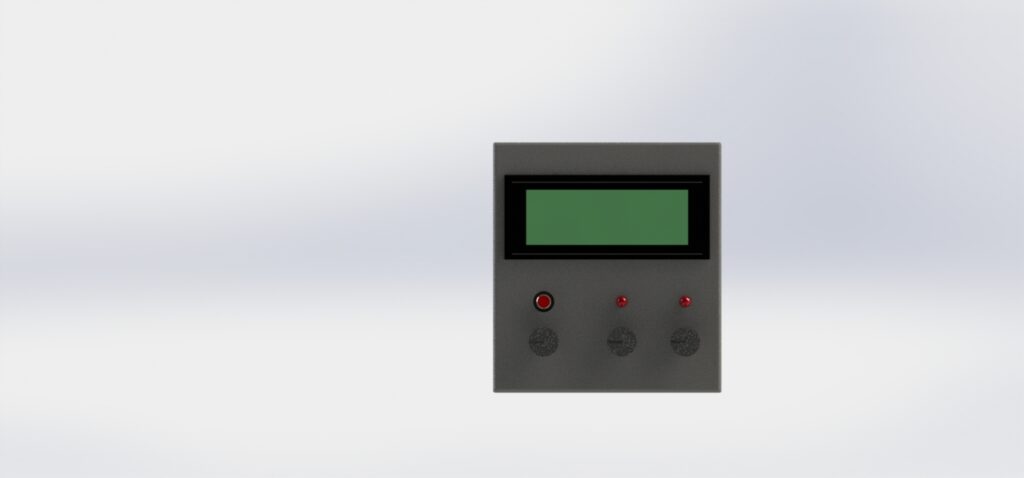

Custom 3D-Printed Enclosure of Measurement Wheel Device Project:

To enhance usability and make the device workshop-ready, we designed a custom enclosure using CAD software and 3D printed it using durable PLA material.

Design Highlights:

- Compact layout: All components fit neatly inside the casing.

- Mounting slots: For attaching the device to table saw rails or wood guides.

- Cable routing: Clean internal cable channels for protection and neatness.

- Display window: Transparent panel for the LCD.

- Access holes: Easy access to encoders, button, and USB port.

- Ventilation: Slots for airflow to prevent overheating during long sessions.

- Modular Design: Easy to open for updates, repairs, or improvements.

The 3D design ensured precise fits for all electronic parts and a professional look — turning a DIY project into a finished product-grade tool.

Circuit Diagram of Measurement Wheel Device Project with Arduino:

Code for Measurement Wheel Device Project with Arduino:

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

bool Direction=false; // You can change it to false/true to change the measuring direction.

bool UNIT = true;

// LCD setup

LiquidCrystal_I2C lcd(0x27, 20, 4); // Change 0x27 if your LCD has a different address

// Rotary Encoder Pins

// Encoder 1 - for screen change / blade thickness

#define ENC1_CLK 10

#define ENC1_DT 11

#define ENC1_BTN 12

// Encoder 2 - Angle 2

#define ENC2_CLK 7

#define ENC2_DT 8

// Encoder 3 - Angle 3

#define ENC3_CLK 4

#define ENC3_DT 5

#define encoderPinA 2 // Must be interrupt-capable pin

#define encoderPinB 3

volatile long pulseCount = 0;

float distance_mm = 0, distance_mm_raw, last_distance_mm, prev_distance_mm_raw, Distance;

float V_Extra, S_Extra ;

float wheel_dia = 12; //Here you can edit the wheel diameter in mm

float encoder_impulse = 600; //Here you can edit Encoder impulse

float wheel_circum, mm_pr_imp, W_delay;

// Push Button

const int clearButton = A0;

char R, Btn; bool EditB = false, EditW = false, EditU = false;

// RGB LED pins

const int led1Red = 6;

const int led1Green = 9;

const int led2Red = A2;

const int led2Green = A3;

bool flag1=true;

// Variables

int screen = 0; // 0 = Angle Display, 1 = Blade Thickness Edit

float Blade_size = 2.6;

int angle2 = 0;

int angle3 = 0;

int lastState1, lastState2, lastState3;

int pos1=0, pos2=1, pos3=1;

int lastPos1 = 0, lastPos2 = 0, lastPos3 = 0;

void setup() {

Serial.begin(9600);

// LCD setup

lcd.begin();

lcd.backlight();

lcd.clear();

// Encoder pins

pinMode(ENC1_CLK, INPUT);

pinMode(ENC1_DT, INPUT);

pinMode(ENC1_BTN, INPUT_PULLUP);

pinMode(ENC2_CLK, INPUT);

pinMode(ENC2_DT, INPUT);

pinMode(ENC3_CLK, INPUT);

pinMode(ENC3_DT, INPUT);

// RGB LED pins

pinMode(led1Red, OUTPUT);

pinMode(led1Green, OUTPUT);

pinMode(led2Red, OUTPUT);

pinMode(led2Green, OUTPUT);

// Push button

pinMode(clearButton, INPUT_PULLUP);

pinMode(encoderPinA, INPUT);

pinMode(encoderPinB, INPUT);

// Attach interrupt on encoder A

attachInterrupt(digitalPinToInterrupt(encoderPinA), encoderAISR, RISING);

lastState1 = digitalRead(ENC1_CLK);

wheel_circum = PI*wheel_dia;

mm_pr_imp = wheel_circum/encoder_impulse;

displayScreen();

W_delay = Blade_size + V_Extra + S_Extra;

}Working Video of Measurement Wheel Device Project:

Applications of Measurement Wheel Device:

This Device is purpose-built for woodworking applications, especially where accuracy and repeatability matter.

Table Saws:

- Track how much wood has been cut in real-time.

- Ideal for cutting multiple pieces to the same length.

Sliding Saws or Panel Saws:

- Measure travel length during each pass.

- Great for repetitive angled or beveled cuts.

Custom Woodworking Jigs:

- Integrate with fences, guides, or rollers for dynamic cut measurement.

Woodworking Education:

- Teach measurement, tool calibration, and real-time feedback systems.

Conclusion:

This Wood-Cutting Saw Length Measuring Device transforms your table saw or cutting station into a smart measurement platform, helping ensure every cut is accurate, consistent, and accounted for. With support for blade kerf and tilt angle corrections, it provides real-world usability that aligns with professional woodworking needs.

If you’re serious about clean, accurate cuts and want to minimize waste while maximizing efficiency — this project is your perfect digital woodworking assistant.

Need This Project?

If you need this Project with or without Modifications or Customization then you can contact us through WhatsApp. We can deliver you this Project in the Following Ways.

Project Code:

we can provide you Project Code along with Zoom Assistant, through Zoom meeting for Setup of this Project or any other Arduino Project of your need.

Fully Functional Project with Hardware/Components Shipment:

if you can not make this project yourself then you can use this option. We will assemble the Project and will ship it to your Doorstep with Safe Packaging.

Learn More about the services we offer.