In many industrial and laboratory processes, it is essential to dose precise quantities of powdered materials into water or other solvents to prepare chemical or solution mixtures. Manual powder handling is often inconsistent, messy, and prone to human error — especially in applications where the accuracy of concentration directly affects product quality or chemical reactions.

To overcome these challenges, our team at Arduino Expert designed and developed a Smart Powder Dosing and Solution Mixing System using the M-DUINO 21 Plus PLC, an Arduino-based industrial controller.

This device automates the complete process of:

- Dosing the powder from a storage tank,

- Mixing it into the water tank,

- Allowing maturation for 12 hours, and

- Discharging the solution automatically each day.

The system is not only precise and reliable, but also IoT-enabled, allowing remote monitoring and control over HTTPS using a Ethernet.

By combining Arduino’s flexibility with PLC-level robustness, the project demonstrates how open-source control can be applied in real industrial automation with long-term reliability.

Project Overview: Smart Powder Dosing and Solution Mixing System

The Powder Dosing Device was developed to automatically prepare a powder-based solution on a 24-hour cycle. The system measures the amount of powder and water required, mixes them, waits for a maturation period, and then releases the solution for further use.

Key Operations of System:

- Powder Dosing — Controlled by a stepper motor driving an auger screw (100 g per revolution).

- Water Filling — Managed by two valves (inlet and outlet) and monitored by two level switches (empty/full).

- Mixing & Pumping — Using a water pump to circulate water for 10 minutes after dosing.

- Maturation Period — The mixture is held for 12 hours.

- Solution Disposal — Pump and outlet valve release the solution automatically.

- Daily Cycle — Entire process repeats daily as per schedule.

All parameters — start time, powder amount, and maturation duration — are stored in the PLC memory and can be updated remotely from the client’s cloud server.

What is M-DUINO 21 Plus PLC?

The M-DUINO 21 Plus from Industrial Shields is an industrial-grade PLC built around the Arduino Mega 2560 microcontroller. It combines the simplicity of Arduino programming with the durability and safety features required for industrial environments.

Key Features of M-DUINO 21 Plus PLC:

- 21 configurable I/O points (analog and digital)

- 12–24 V DC power supply

- Opto-isolated inputs/outputs for electrical protection

- Ethernet, RS-485, RS-232, I²C, and SPI communication interfaces

- Compatible with Arduino IDE (C/C++ programming)

- Compact DIN-rail mountable enclosure

- Built-in watchdog timer and fail-safe restart

For this project, M-DUINO was the perfect choice because it allowed integration of industrial sensors, relays, and communication modules within a reliable automation framework.

Why We Used a PLC Instead of a Simple Arduino Board?

While a basic Arduino Uno or Mega can easily control relays, motors, and sensors, it lacks several crucial features for long-term industrial operation.

The M-DUINO PLC, on the other hand, is designed specifically for reliability, safety, and scalability.

Key Reasons for Choosing PLC over Arduino:

- Industrial Power Compatibility:

- PLC operates directly on 12–24 V DC, unlike Arduino boards that require 5 V regulators or adapters.

- Electrical Isolation:

- M-DUINO has opto-isolated inputs and outputs, protecting the controller from high-voltage spikes from motors and relays.

- Noise Immunity:

- Industrial PLCs are designed to operate reliably in environments with electrical noise, pumps, and inductive loads.

- Fail-Safe Operation:

- Built-in watchdog system ensures automatic recovery after power loss.

- Professional Wiring & Enclosure:

- Screw terminals, DIN-rail mount, and organized wiring make installation clean and safe.

- Multiple Communication Interfaces:

- PLC supports Ethernet, RS-485, RS-232, and GSM — essential for IoT communication.

- Remote Configuration:

- Easy to integrate HTTPS-based control and data transmission.

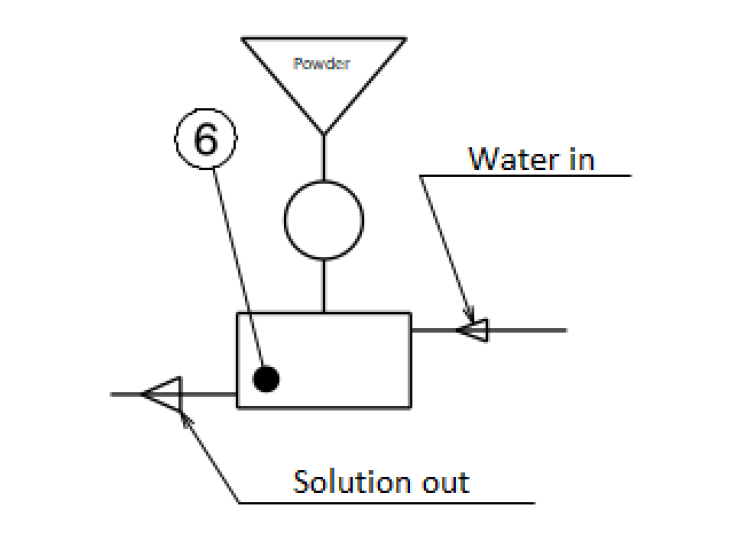

Working Principle of Smart Powder Dosing and Solution Mixing System

The system performs a complete daily dosing and mixing cycle automatically according to the programmed schedule and settings stored inside the PLC.

Each phase of the process is precisely controlled to ensure consistency and accuracy.

Step-by-Step Process Flow of Smart Powder Dosing and Solution Mixing System

- System Initialization

- At the programmed start time, the PLC checks the status of the water tank using two level switches (empty & full).

- If the tank is empty, the inlet water valve is activated (via relay) to fill the tank until the full-level switch closes.

- Powder Dosing

- Once the tank is full, the stepper motor starts rotating the dosing screw (auger).

- Each revolution of the auger dispenses approximately 100 grams of powder from the powder tank into the water tank.

- The total number of rotations is determined by the desired powder quantity set in the controller.

- Mixing Stage

- After dosing, the water pump runs for 10 minutes while the outlet valve remains closed.

- The recirculating water pipe connected from the top of the tank ensures proper mixing of the powder and water.

- Maturation Period

- The solution is allowed to mature for 12 hours (or the time defined in the system settings).

- During this period, the PLC keeps the device in standby mode.

- Solution Discharge

- After the maturation time elapses, the outlet valve is opened.

- The pump starts again to discharge the prepared solution until the empty-level switch detects an empty tank.

- Daily Cycle Completion

- Once the tank is emptied, the system goes into idle mode and waits for the next scheduled start time to repeat the process.

IoT & Remote Control via Ethernet

The device is equipped with Ethernet, allowing it to:

- Send periodic status updates to the client’s central server every 5 minutes, including:

- Device ID (IMEI)

- Timestamp

- Status of level switches, valves, pump, and motor

- Powder-level sensor readings

- Receive remote configuration commands (such as start time, powder quantity, or maturation duration) from the server via HTTPS communication.

This enables real-time monitoring, remote diagnostics, and parameter updates from anywhere, making the system ideal for unattended or remote installations.

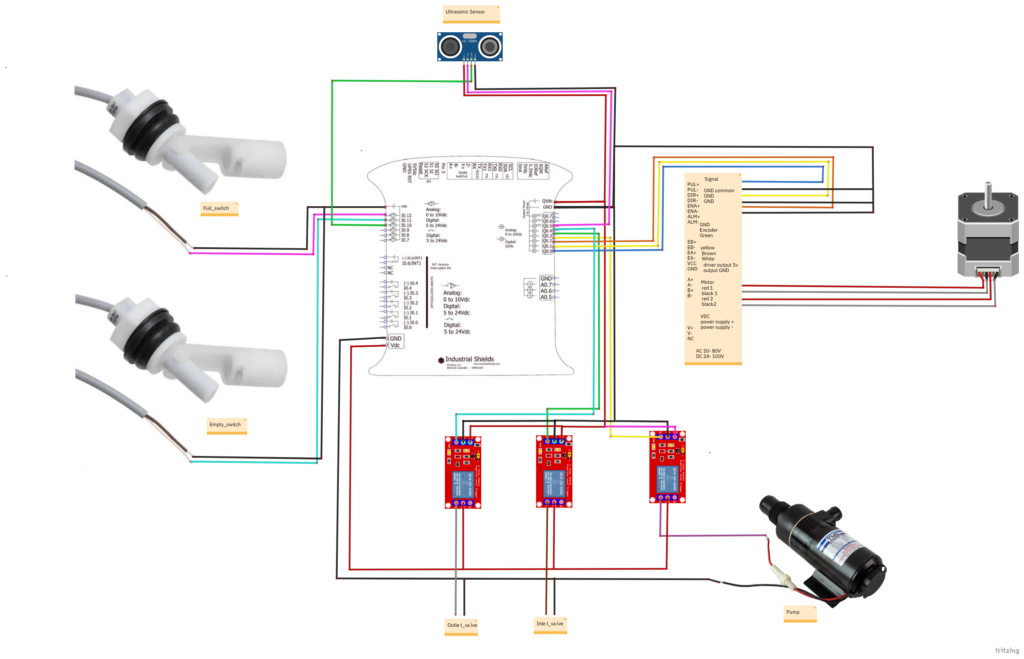

Components used in Smart Powder Dosing and Solution Mixing System

| Component | Function | Interface with PLC |

|---|---|---|

| Ultrasonic Sensor (Waterproof) | Measures powder level in the tank | Digital |

| Stepper Motor + Auger | Controls precise powder dosing | Digital output (step/dir signals) |

| Water Pump | Circulates water and discharges solution | Relay output |

| Water Inlet Valve | Controls water entry | Relay output |

| Water Outlet Valve | Controls discharge | Relay output |

| Level Switches (Full & Empty) | Detect tank fill/empty status | Digital inputs |

Circuit Diagram of Smart Powder Dosing and Solution Mixing System with M-DUINO 21 Plus PLC

Data Logging & Recovery of System

The PLC maintains internal status variables and timestamps.

In the event of a power interruption, the system automatically resumes from the last known process stage.

If power is restored after the maturation period, it directly proceeds to the solution discharge phase and then returns to idle mode, ensuring no process data is lost.

Applications of Smart Powder Dosing and Solution Mixing System

This smart dosing system can be used across multiple industries requiring precise and repeatable solution preparation:

- Chemical Processing Plants – For accurate powder-to-liquid formulation.

- Water and Wastewater Treatment – For chlorine, lime, or coagulant dosing.

- Food and Beverage Industry – For mixing powdered ingredients or flavorings.

- Pharmaceutical and Laboratory Automation – For precise reagent preparation.

- Agriculture and Fertilizer Mixing – For solution-based nutrient dosing systems.

The flexibility of the M-DUINO platform also allows future expansion — for example, adding temperature monitoring, flow sensors, or web dashboards.

Benefits of Our Solution

- High dosing precision (controlled auger motor)

- Efficient water management (automated valves & switches)

- Daily auto-cycle with zero manual input

- IoT monitoring and cloud connectivity

- Power-loss recovery (fail-safe restart)

- Industrial-grade durability

- Easy future customization using Arduino IDE

Conclusion

The Smart Powder Dosing and Solution Mixing System using M-DUINO 21 Plus PLC is a milestone in industrial automation using Arduino technology.

It demonstrates how open-source platforms can be transformed into robust, industrial-grade machines when paired with the right hardware architecture.

By integrating stepper control, valve logic, IoT connectivity, and automated scheduling, the system delivers precise and reliable performance every day.

This project exemplifies Arduino Expert’s expertise in product design and development, automation engineering, and IoT-based industrial solutions — bridging the gap between prototype electronics and full-scale industrial automation.

Need This Project?

If you need this Smart Powder Dosing and Solution Mixing System with or without Modifications or Customization then you can contact us through WhatsApp. We can deliver you the Fully Functional Project with Hardware/Components Shipment:

if you can not make this project yourself then you can use this option. We will assemble the Project and will ship it to your Doorstep with Safe Packaging.

Learn More about the services we offer.