In the field of automation and mechatronics, linear actuators and slider systems play a crucial role in enabling precise, repeatable motion control for a wide range of industrial and commercial applications. From camera sliders and CNC machines to material feeders and positioning systems, these mechanisms are vital for tasks that require accurate, automated linear movement.

In this project, developed by Arduino Expert, we designed a Linear Actuator and Slider Control System using Arduino that can automatically move between two end limits using limit switches for boundary detection and a potentiometer for adjustable speed control. The movement is powered by a stepper motor, ensuring high precision, reliability, and repeatability.

The main objective of this project is to demonstrate how Arduino-based motion control can be effectively utilized in product design and development, automation systems, and prototyping setups. By integrating electronic control, mechanical actuation, and sensor feedback, this project bridges the gap between hardware design and intelligent motion control — providing a practical and scalable foundation for automation engineers, product designers, and students.

This project highlights the importance of Arduino programming and embedded control logic, showing how a simple microcontroller can be transformed into a powerful motion controller capable of handling linear motion with accuracy and safety.

Project Overview: Automated Linear Actuator and Slider System

The Automated Linear Actuator and Slider System uses an Arduino UNO to control the direction and speed of a stepper motor, which drives a lead screw or belt mechanism to produce linear movement.

Two limit switches are placed at both ends of the actuator’s path to define its travel range. These switches act as safety stops — when triggered, they signal Arduino to reverse the motor’s direction to prevent over-travel.

A potentiometer is integrated into the circuit to allow real-time speed adjustment of the actuator, enabling smooth and flexible motion control.

The result is a fully automated linear actuator that continuously moves back and forth between two end points — ideal for use in applications like camera sliders, automated testing equipment, and CNC motion systems.

Working Principle of Automated Linear Actuator and Slider System Control Project

The working of the system can be understood through the following steps:

- System Initialization

When powered ON, the Arduino initializes the stepper motor and reads the potentiometer value to determine the operating speed. The actuator begins movement in one direction (e.g., forward). - Forward Travel

The stepper motor rotates in the forward direction, causing the actuator or slider to move linearly toward Limit Switch 1. Once the switch is pressed, Arduino immediately stops the motor. - Automatic Direction Reversal

After reaching Limit Switch 1, the Arduino reverses the motor’s direction, allowing the actuator to travel back toward Limit Switch 2. - Reverse Travel and Continuous Loop

When Limit Switch 2 is triggered, the same sequence repeats, creating a continuous back-and-forth sliding motion. - Speed Control

The potentiometer allows the user to adjust the speed of the actuator in real time without restarting the system. The analog voltage from the potentiometer is mapped to control the motor’s stepping delay. - End-Stop Protection

The limit switches ensure the slider stops safely at each end, preventing mechanical damage and ensuring long operational life.

Components Used in Automated Linear Actuator and Slider System Project

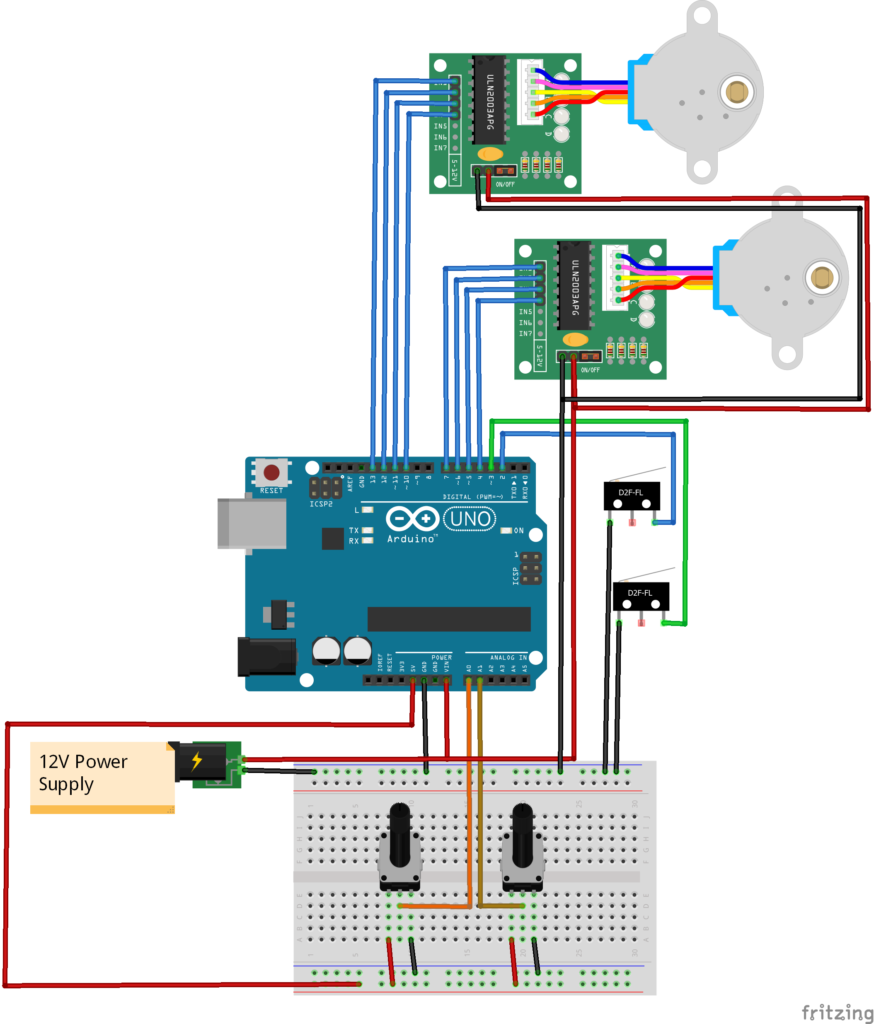

| Component | Description |

|---|---|

| Arduino UNO | Serves as the main controller to manage motor direction, speed, and limit switch input. |

| Stepper Motor (28BYJ-48 / NEMA 17) | Provides precise and controlled linear motion. |

| ULN2003 Driver Board | Acts as an interface between Arduino and the stepper motor. |

| Limit Switches (x2) | Detect end positions and ensure the actuator does not over-travel. |

| Potentiometer (10kΩ) | Allows real-time speed adjustment. |

| Power Supply (5V–12V) | Powers the Arduino and motor driver. |

| Jumper Wires and Breadboard | Used for circuit connections and prototyping. |

Circuit Diagram of Automated Linear Actuator and Slider System with Arduino

Applications of Automated Linear Actuator and Slider System

The Arduino-Based Linear Actuator and Slider System can be adapted to a wide variety of practical and industrial uses:

- Camera Slider System – Provides smooth, repeatable camera movement for time-lapse or cinematic shots.

- Material Feeder Mechanism – Automatically advances materials for cutting, stamping, or packaging.

- CNC Axis Control – Acts as a simple motion control setup for one CNC axis.

- Testing and Measurement Equipment – Enables precise, repeatable motion for endurance or fatigue testing.

- Educational Prototyping – Perfect for demonstrating automation concepts in labs and classrooms.

- Product Design and Development – Can be customized into various actuator-driven systems for new product prototypes.

Advantages Automated Linear Actuator and Slider System Project

- Fully automated back-and-forth linear motion

- Adjustable speed via potentiometer

- Safe operation with dual limit switches

- Cost-effective and reliable design

- Modular and scalable for larger setups

- Perfect for both educational and industrial use

Technical Insights

This project demonstrates key aspects of Arduino Programming and Product Design and Development:

- Motor Control: Implementation of precise stepper motor control using digital pulses.

- Sensor Integration: Use of limit switches for mechanical position feedback.

- Analog Input Mapping: Potentiometer-based real-time speed adjustment.

- Automation Logic: Directional control and continuous looping operation.

- Safety Handling: Proper limit switch integration to prevent mechanical failure.

It’s a strong foundation for learning mechatronics, embedded systems, and industrial automation concepts, where both software and hardware work seamlessly to achieve mechanical precision.

Conclusion

The Automated Linear Actuator and Slider System using Arduino is a versatile and practical project that brings together mechanical motion control, sensor feedback, and embedded programming into a single, intelligent system.

It demonstrates how a simple Arduino-based setup can perform reliable and accurate linear motion control — similar to what is used in industrial automation and robotics.

This project by Arduino Expert showcases the potential of Arduino programming and product design and development to create innovative and real-world motion control systems.

By customizing the mechanical setup or motor type, this same system can be adapted for CNC machines, robotic arms, smart manufacturing prototypes, and other advanced automation applications.

Need This Project?

If you need Automated Linear Actuator and Slider System Project with or without Modifications or Customization then you can contact us through WhatsApp. We can deliver you this Project in the Following Ways.

Project Code:

we can provide you Project Code for Liquid Vending Machine along with Zoom Assistant, through Zoom meeting for Setup of this Project or any other Arduino Project of your need.

Fully Functional Project with Hardware/Components Shipment:

if you can not make this project yourself then you can use this option. We will assemble the Project and will ship it to your Doorstep with Safe Packaging.

Learn More about the services we offer.