In this Project we will make a Container Strap Checking Device for Driver Safety. In the logistics and transportation industry, ensuring the safety of cargo is a top priority. One of the most critical yet often overlooked aspects of cargo safety is the proper strapping of shipping containers. Unsecured or poorly strapped containers can shift during transit, leading to serious road accidents, damage to goods, or injuries to the driver and other road users. To address this issue proactively, we developed an Arduino-based Shipping Container Strap Checking Device — a compact and efficient wireless system designed to assist truck drivers in verifying whether the container straps are securely fastened before commencing their journey.

Working Principle of Container Strap Checking Device:

This safety device consists of two main components: a Sender Unit, which is mounted near the strap mechanism of the container, and a Receiver Unit, placed inside the truck’s cabin for the driver to monitor. The Sender Unit uses a limit switch to detect the physical presence of the strap. When the strap is properly secured, the switch is pressed; if not, it remains open. The state of this switch is monitored by an Arduino Nano, which then transmits the strap status wirelessly using an HC-12 transceiver module.

The Receiver Unit, also powered by an Arduino Nano and equipped with a second HC-12 module, receives this information and visually communicates it to the driver using Green and Red LEDs. A Green LED indicates that the strap is secure, while a Red LED warns the driver of a potential safety risk due to an unsecured strap. This setup provides immediate, clear feedback to the driver without requiring physical inspection of the container, thereby saving time and enhancing safety.

Power is supplied to both units via independent batteries, allowing the system to function autonomously and reliably in any mobile transport environment. The simplicity, reliability, and cost-effectiveness of this project make it an ideal solution for fleet operators, logistics companies, and individual truckers focused on safety compliance.

Components required for Container Strap Checking Device:

1. Sender Side (Strap Detection Unit):

- Arduino Nano

- Limit Switch

- HC-12 Wireless Transceiver Module

- Battery (Li-ion or 9V, depending on design)

2. Receiver Side (Driver’s Indicator Unit):

- Arduino Nano

- HC-12 Wireless Transceiver Module

- Red LED (Strap not secured)

- Green LED (Strap secured)

- Battery

Working of Container Strap Checking Device:

The device consists of two main units:

Sender Side:

- Installed near the container strap mechanism.

- A limit switch is mounted in such a way that when the strap is secured properly, it presses the limit switch.

- The Arduino Nano constantly monitors the state of the limit switch.

- If the strap is secured (switch pressed), the Arduino sends a “STRAP_OK” signal through the HC-12 transceiver.

- If the strap is not secured (switch released), the Arduino sends a “STRAP_FAIL” signal instead.

Receiver Side:

- Placed inside the truck cabin, easily visible to the driver.

- The HC-12 receiver continuously listens for messages from the sender.

- The Arduino Nano reads the incoming signal:

- If it receives “STRAP_OK”, the Green LED is turned ON, and the Red LED is turned OFF.

- If it receives “STRAP_FAIL”, the Red LED is turned ON, and the Green LED is turned OFF.

- This provides a clear visual indication to the driver about the safety status of the container strap before and during transit.

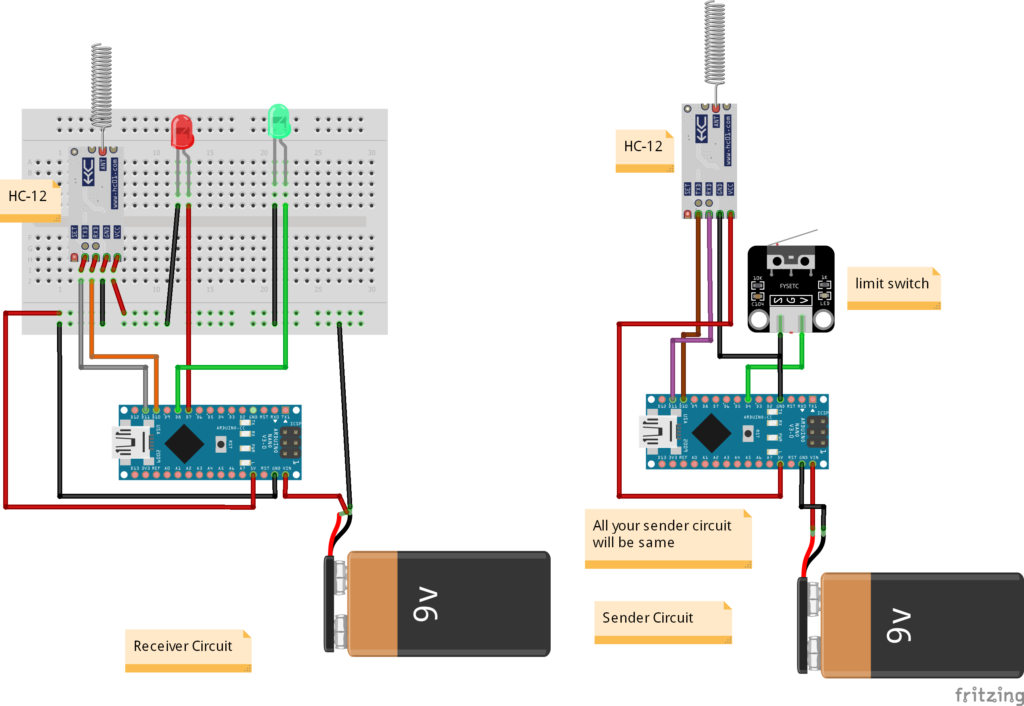

Circuit Diagram of Container Strap Checking Device with Arduino Nano:

Sender Side:

- Limit Switch:

- One side to GND

- Other side to digital pin (e.g., D2) with pull-up logic

- HC-12 TX & RX connected to Arduino RX & TX (using software serial to avoid conflict)

- Power Supply from battery connected to VIN and GND

Receiver Side:

- Green LED: Connected to a digital pin (e.g., D3) via resistor

- Red LED: Connected to another digital pin (e.g., D4) via resistor

- HC-12 TX & RX connected similarly to software serial pins

- Battery power to Arduino and HC-12

Benefits of the Container Strap Checking Device:

- Enhances driver awareness regarding the strap status.

- Prevents accidents or damage due to unstrapped containers.

- Wireless communication ensures a clean and flexible installation.

- Uses low-power components, ideal for mobile applications.

- Can be easily scaled to multiple straps or points.

Possible Improvements in Container Strap Checking Device:

- Use a buzzer in the driver unit for audio warning.

- Integrate with a GSM module to notify the fleet manager if the strap is not secured.

- Add multiple limit switches if there are more than one strap points.

- Include a display to show real-time strap status or alerts.

Need This Project?

If you need this Project with or without Modifications or Customization then you can contact us through WhatsApp. We can deliver you this Project in the Following Ways.

Project Code:

we can provide you Project Code along with Zoom Assistant, through Zoom meeting for Setup of this Project or any other Arduino Project of your need.

Fully Functional Project with Hardware/Components Shipment:

if you can not make this project yourself then you can use this option. We will assemble the Project and will ship it to your Doorstep with Safe Packaging.

Learn More about the services we offer.